Water Smart Cities Project

Article

Article

Aerobic biological treatment of wastewater relies on the injection of air into a tank to provide the biomass present there with the oxygen it requires to oxidize the organic matter making up the pollutant load. Aeration is generally the main source of energy expenditure, accounting for 40 to 60% of electricity consumption. Selecting the right parameters for aeration control is a complex task for operators. Whether it's a question of aeration duration, oxygen concentration setpoint or sludge concentration, there are a large number of levers impacting purification operation. It is then necessary to find the best compromise between energy consumption, the quality of the water discharged, the quantity of sludge produced…

This is why CEBEDEAU, in collaboration with and on behalf of SPGE, has carried out an extensive two-part study:

The first consists of a theoretical study of the means available to the operator to reduce energy consumption, without compromising treatment performance.

This chapter highlights the importance of meticulous design of aeration equipment, but also of biological basins, as well as regular maintenance of equipment when it comes to achieving energy savings.The study also emphasizes the effect of choices made during operation. This was studied in greater detail in the second part of the study.

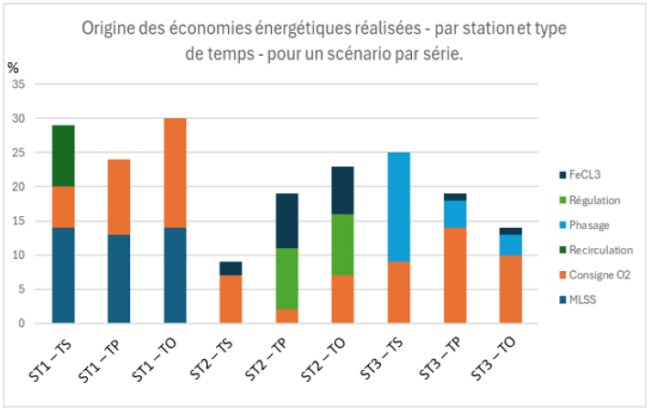

The second part consists of a pseudo-experimental study based on modeling to identify as precisely as possible the impact of different choices of operational parameters. Three Walloon wastewater treatment plants were fully modeled using WEST® software (DHI). Starting from a reference scenario, the parameters identified as potential levers were incremented, and the effects on energy consumption and treatment quality were recorded. In this way, the potential for energy savings was mapped out.

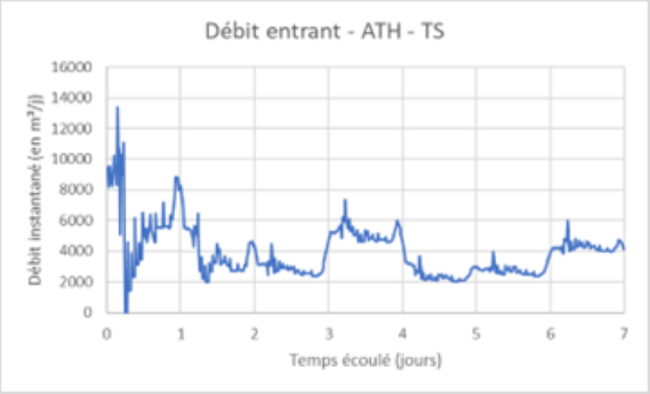

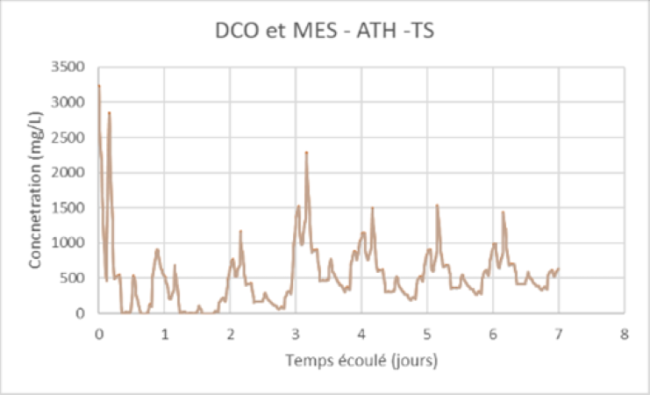

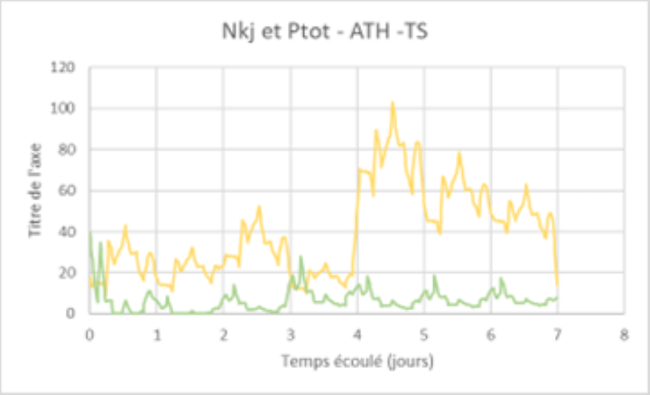

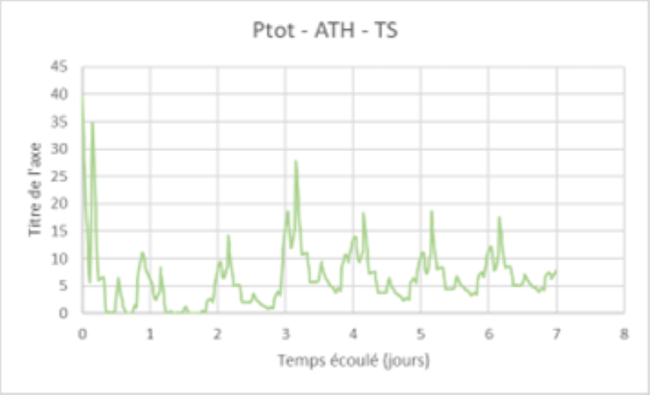

To achieve this result, it was necessary to look at variations in plant inlet loads. A statistical method for reconstructing the influent profile based on 24-hour profiling was developed for this purpose. Scenarios were established for dry weather, rainy weather and stormy showers. Once again, statistical methods were used, drawing on regular analyses carried out by the stations as well as measurements made specifically for this purpose.

We have also developed indicators that allow us to compare energy expenditure while taking into account the quality of the influent. They enable rigorous comparisons to be made between different situations. These indicators include other aspects such as the energy devoted to recirculation and sludge production. Indeed, a gain in aeration could theoretically be offset by a negative impact at another point in the process. The proposed indicators enable all these aspects to be taken into account simultaneously. Conversely, choices linked to processes other than the aerobic degradation of organic substances can have an influence on aeration. One example is the use of ferric chloride for phosphate removal, which affects oxygen demand by reducing the biomass content of the mixed liquor.

It appears that, as things stand, operators make choices that ensure safe processing under all conditions, with minimum energy expenditure. In most cases, it is impossible to adjust operating parameters “in real time”, so a permanent choice is made, which is a compromise capable of coping with all situations. Improving the energy efficiency of stations therefore means making the system more responsive to weather conditions and load variations, which can be achieved by using advanced control systems. Of course, for such a system to be justified, it must be profitable, which is mostly the case for medium- and large-capacity stations.

The study also highlighted the disparities between stations. Indeed, the plants selected in this context use different processes, some using continuous aeration, others alternating aeration, some using physico-chemical phosphorus removal, and others using a biological process for phosphorus elimination. In addition, influent characteristics also differ between regions, mainly due to different dilution factors.

Modeling is therefore an effective tool for understanding the complexity inherent in modern biological treatment plants. It can be used to represent the interactions between different sectors or processes in the purification chain. It can also be used to quantify subtle effects or to compare antagonistic effects.

We would like to thank Olivier Parent of Ipalle, Lény Barras of IDELUX and Christophe Leton of InBW for access to their data and their invaluable contribution to this project. Our thanks also go to Mr. Nicolas Staelens, who monitored the project on behalf of SPGE.

Article

Article

Event