Water Smart Cities Project

Article

Article

The Yara Tertre joint wastewater treatment plant project, located in the Tertre-Villerot-Hautrage eco-zoning (Saint-Ghislain in the Borinage region), is progressing apace. The construction phase began in 2023, with commissioning scheduled for 2025. The station is designed to meet the latest European standards. Meanwhile, the teams - including Trevi Environmental Solutions - responsible for construction, operation and maintenance, are hard at work. Designed to treat outgoing eco-zoning water, this plant will ultimately greatly reduce the ecological impact of the site's activities. The project meets the requirements of the plant's operating permit and is part of Yara's overall environmental strategy.

Yara International ASA is a global group offering crop nutrition solutions that enable farmers to increase yields and improve product quality while reducing environmental impact. With its various industrial sites, Yara has a strong presence in the Benelux. These produce - among other things - a wide range of fertilisers that make it easier to support farmers and meet the large demand for industrial solutions.

At the Tertre site, located in the aforementioned zoning area, the group mainly produces fertilisers as well as nitric acid and industrial solutions. Meeting the requirements of the SEVESO high threshold regulations, it employs around 300 people directly, plus around a hundred contractors.

The Yara wastewater treatment plant project is financed and managed by Yara, but it is the result of a consortium of eco-zoning companies. To put it plainly, as part of the joint use of this plant, Yara will enter into service contracts with the participating companies, the invoicing of which will depend on the quantity and quality of the water to be treated. The number of companies using these services may naturally increase over time, enabling even greater volumes of water to be treated in the future. At the current stage of the project, the 2-hectare plant should be able to treat 10,000 m3/day, but depending on how it evolves, this capacity could be increased to a maximum of 20,000 m3/day.

The CEBEDEAU centre of expertise, which specialises in water treatment, was involved in the project from the outset, carrying out pilot tests on site for a year in 2018 using effluent from the industrial companies concerned. CEBEDEAU then carried out the preliminary study to define the basic data for sizing the treatment plant, drew up the specifications and supported Yara throughout the various phases of the call for tenders. For Yara, the project represents a total investment of almost €20 million.

The call for tenders led to the selection of Trevi Environmental Solutions to build, maintain and operate the plant. The contract between Yara and Trevi is for a renewable ten-year period.

Trevi is a Ghent-based company employing 210 people. It specialises in the environment, and more specifically in water and waste treatment. It is a multi-skilled company, capable of solving all environmental problems in the fields of water, air and energy.

While it is subcontracting three aspects of this project (earthworks, civil engineering and steel structures), it is responsible for everything else, including the electromechanical part, which includes piping, pumps and electricity. This broad spectrum of skills makes it easier to coordinate the work, which Yara is delighted about.

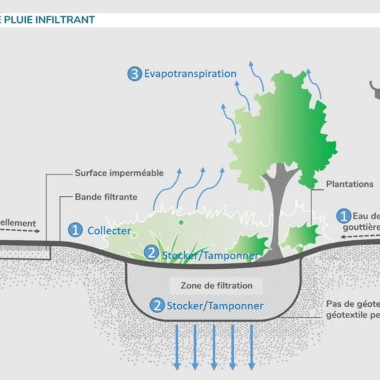

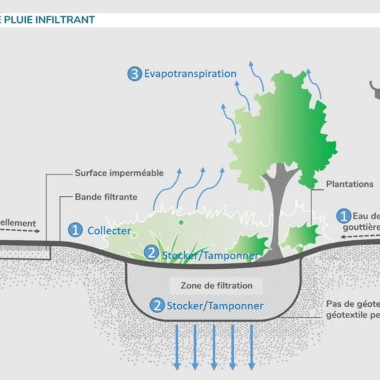

The Yara Tertre wastewater treatment plant collects water from the eco-zoning, i.e. normal water and out-of-specification water (in the event of a calamity on the site), where it undergoes biological treatment before being discharged into the Haine (a tributary of the Scheldt) via a closed drainage system. The plant is also equipped to collect rainwater in the event of heavy rainfall. The aim is to capture rainwater in a 7,000 m3 rainwater buffer tank, then treat it and gradually discharge it into the Haine, thereby flattening out the rainfall peaks and preventing the river from overflowing.

The plant naturally includes all the equipment needed for biological water purification (denitrification/nitrification processes, clarifiers), as well as sludge treatment by mineralisation and dewatering using a centrifugal decanter, in order to reduce the volume of sludge. Odour emissions from the service building are also treated using a biofilter.

Reliability is also one of Yara's priorities. That's why the plant has two treatment lines. This fully redundant system can compensate for any failure and switch to the other line in the event of a malfunction on the first.

In addition, an end-of-pipe control system monitors the quality of the water discharged into the river Haine, using in-line analysers and sensors (TOC/TN/TP/pH). This obviously has a positive impact on the final quality of the water in the Haine. Once again, Yara is demonstrating its great concern for the environment.

The Yara Tertre wastewater treatment plant is also a circular economy project. As part of the purification process, nitrogen treatment requires large quantities of carbon sources (20,000 tonnes per year). But this is very expensive. Hence the need to find alternative sources, which has proved possible thanks to an international network. Yara recovers carbon sources from other companies and recycles waste that would otherwise probably not have been recycled. This still recent cooperation also strengthens the overall environmental aspect of the project.

By Michel Hanoulle

Article

Article

Event