Microsens Project

Read the article Microsens ProjectDevelopment of Microbial Bioindicators and Biomarkers for Water Quality Assessment

Article

What if AI was a help in our wastewater treatments ?

Wastewater treatment is a complex operation that must meet increasingly stringent environmental and economic standards. To meet these challenges, the eWatLink project, a collaboration between SPGE and CEBEDEAU, was developed to apply innovative solutions based on advanced digitization, artificial intelligence (AI), and smart control technologies to wastewater treatment plants (WWTPs).

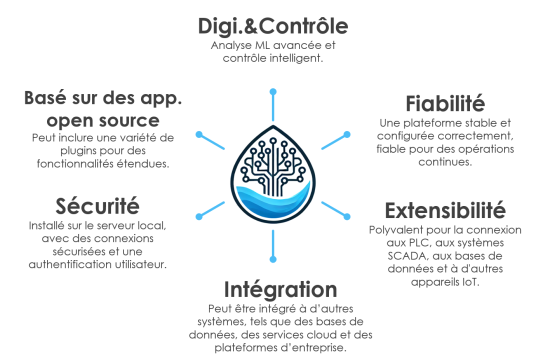

eWatLink is fully in line with the digital transformation of the water sector. It is an advanced management system designed to interconnect physical infrastructure with sophisticated IT platforms. The main objective is to optimize the operational performance of WWTPs in real time, particularly in terms of energy consumption, treatment quality, and reduction of greenhouse gas (GHG).

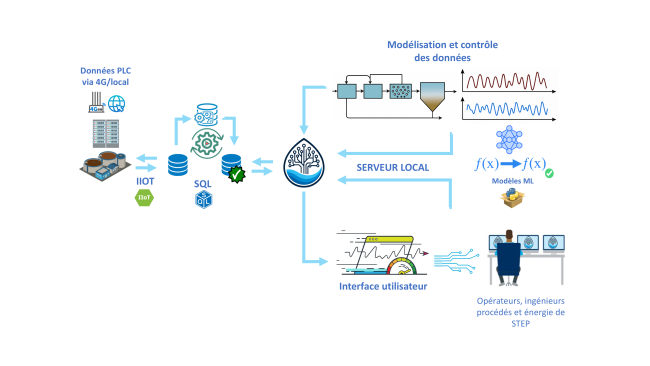

eWatLink is based on open source applications and an architecture combining real-time data from station sensors/machines, secure local servers, SQL database integration, and IoT protocols such as Modbus. The system provides real-time bidirectional data flow: data from physical sensors and software is collected and transferred to a secure local server where it is processed.

The eWatLink data pipeline, illustrated in the attached figures, highlights how this data is structured and used. The collected data is pre-processed to eliminate any outliers or noise before being fed into advanced machine learning (ML) and predictive control models. These algorithms enable the analysis, prediction, and optimization of treatment processes, while also integrating external data such as electricity prices.

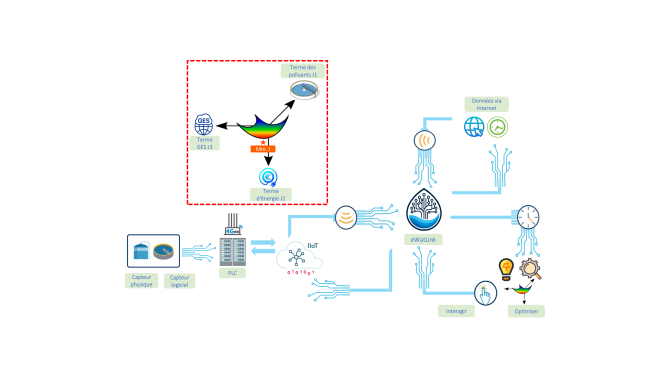

The innovative core of eWatLink is the use of advanced smart controllers that simultaneously optimize several criteria defined in an “objective function.” This mathematical function makes it possible to find an optimal compromise between operational requirements (treatment quality, energy efficiency, emissions reduction). This smart control is dynamic and can be adjusted by operators according to current operational and economic priorities.

To implement nonlinear predictive control (nMPC) of the ventilation system, models were developed based on data collected directly from industrial sensors (air flow rates, dissolved oxygen, etc.), which were used as input and output variables. Two types of models were explored: a black box model using a state space neural network, capable of learning the behavior of the system without requiring a detailed physical description, and mechanistic models based on ASM (Activated Sludge Model) equations, which are closer to the actual operation of the process. Several structures were tested in order to reconcile accuracy, simplicity, and robustness, with the aim of providing operators with a high-performance, reliable control solution that can be adapted to their industrial environment.

In addition to advanced objective-based control, other intelligent control approaches are being developed to optimize treatment processes, such as rule-based controllers (RBC), fuzzy controllers (FC), and adaptive controllers (AC). These strategies enable fine-tuning to variable operational and economic conditions. For example, economic fuzzy controllers incorporate fuzzy logic to dynamically adjust air flow setpoints based on nitrogen loads and different electricity price ranges. These approaches also exploit seasonal trends in nitrogen load to improve the energy and environmental performance of treatment, while taking into account dynamic energy costs.

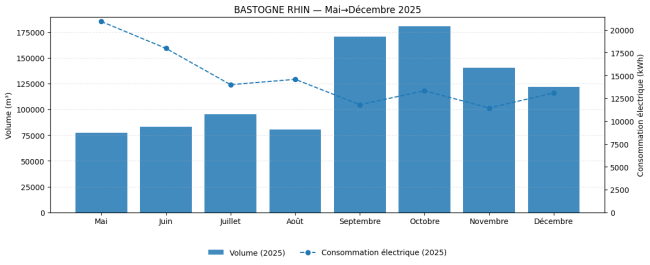

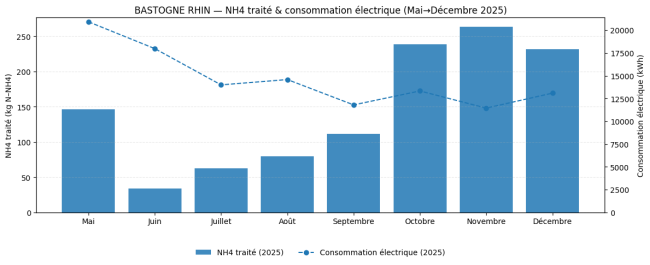

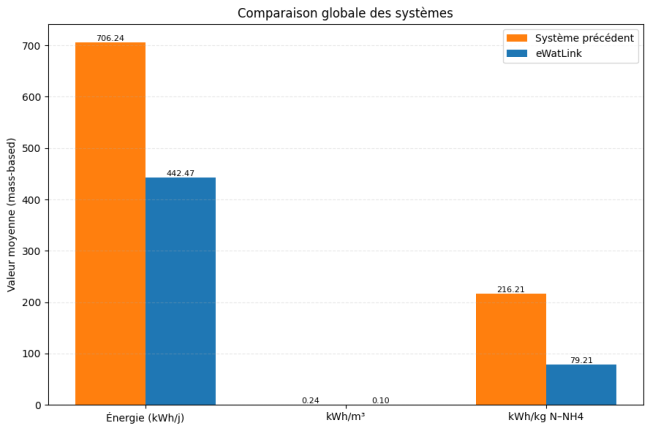

In July 2025, the eWatLink smart system reduced average daily energy consumption by 35% and 37% respectively compared to May 2025 and June 2025, periods operated with the old system. Part of these gains comes from avoiding consumption peaks associated with the full-load operation of ventilation blowers.

These reduction rates may vary from day to day and month to month: they depend mainly on the incoming ammonia loads to be treated, which fluctuate naturally.

Thanks to intelligent control, electricity price signals are automatically retrieved and fed into the control algorithms. The system thus knows the current price and adapts the aeration accordingly: when prices are low, more generous aeration is allowed; when prices are high, weightings/constraints limit aeration. These trade-offs incorporate process safeguards to ensure successful nitrification in all circumstances and to comply with regulatory limits for total nitrogen in discharges.

In addition, eWatLink incorporates virtual “soft sensors” that take over in the event of physical sensor failure (e.g., NH4, NO3). Based on mechanistic and/or machine learning models, they estimate missing values online, simulate sensor behavior, and thus maintain reliable control until the instruments are restored.

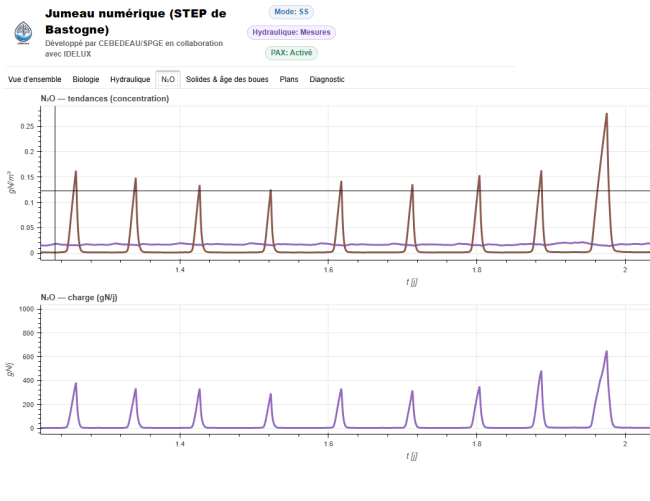

From an environmental perspective, eWatLink actively contributes to reducing greenhouse gas emissions, particularly nitrous oxide (N₂O), while maintaining or even improving water treatment quality.

N₂O is produced during the biological removal of nitrogen; it is a by-product of bacterial metabolism, the formation of which increases when process conditions are suboptimal or the balance of processes is disturbed.

As part of a campaign to monitor N₂O in the liquid phase (using Unisense sensors), which began last year and is still ongoing, we have observed that in intermittent aeration activated sludge processes—widely used in Belgium— N₂O emission peaks are frequently triggered during the transition from nitrification to denitrification, i.e., immediately after aeration is stopped.

Several mitigation measures exist: targeted carbon input, short bursts of aeration, and improved mixing. In the eWatLink project, a very short aeration phase was activated at the time of switching and the quality of the mixture was improved in order to avoid peaks. These actions mitigated the maxima and reduced N₂O emissions by around 30%.

At the end of the analysis, one key lesson stands out: a significant proportion of excess aeration consumption is due to oversized blowers/superchargers. When designing or renovating a WWTP, it is advisable to use different sizes, incorporating at least one small supercharger. This allows for finer adjustment and more stable control of dissolved oxygen, without over-aeration. It also helps prevent N₂O spikes through short air pulses.

In addition to its advanced control, eWatLink offers real-time analysis tools for the entire WWTP. These tools include the aggregation and classification of sensor data, direct estimation of oxygen transfer efficiency in water (kla), organic load relative to biomass (F/M ratio), and analysis of the final state of clarifiers (using the State Point Analysis (SPA) method, for example).

Daily indicators (KPIs) are generated for energy and environmental audits, enabling the assessment of overall consumption and that of sub-processes. Finally, artificial intelligence models are used for clustering, simulation, and forecasting of input data (influential), thus ensuring greater anticipation and responsiveness in operational management.

These results illustrate the overall effectiveness of the system in terms of energy optimization, operational reliability, and environmental performance. The prospects for the eWatLink project are particularly promising: implementation of the system has begun at another IDELUX wastewater treatment plant, in Saint-Hubert, with the aim of replicating and amplifying the energy and environmental gains already demonstrated.

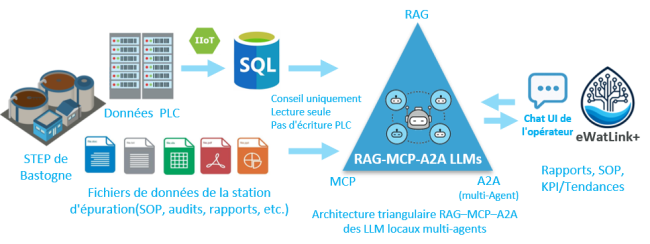

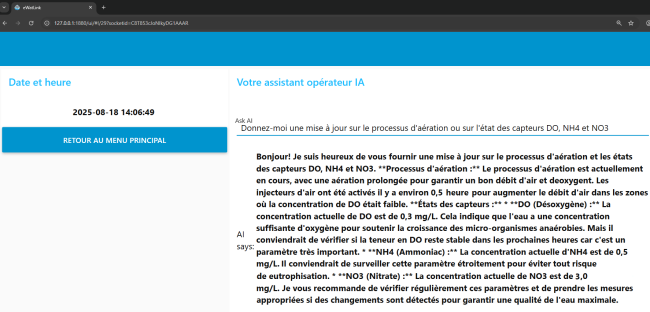

eWatLink+: Local intelligent assistant at the Bastogne WWTP (advice mode only)

As part of eWatLink, we are developing an intelligent assistant, comparable to a local “ChatGPT,” installed directly at the Bastogne WWTP site. This tool is designed to support operators and managers by providing them with quick answers, text suggestions, and preliminary reports. The goal is simple: to facilitate daily work while leaving decisions to operations.

The assistant is fed in read-only mode by two main sources:

Real-time data automatically recorded in the tracking database (MySQL).

Essential station documents (operational procedures, audits, reports, analyses, etc.).

With this access, they can cross-reference WWTP information with internal documentation to provide clear and immediate support. For example, they can explain trends observed in measurements, refer to best practices described in SOPs, or propose a first draft of a report based on the most recent data.

A fundamental point: the assistant remains strictly advisory. It does not control the installation, nor does it modify anything in the PLCs or SCADA. All of its proposals are validated by supervisors. This ensures safe, transparent use that complies with safety and data protection regulations.

In other words, eWatLink+ acts as an augmented memory and writing assistant, always up to date thanks to data from the WWTP, but without ever interfering with its operation.

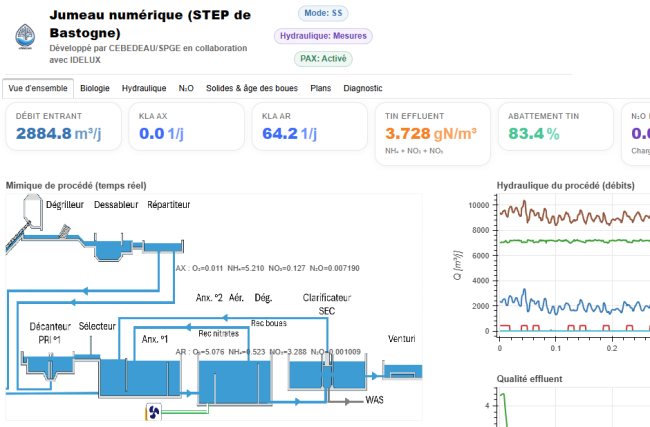

A major recent innovation is the implementation of a complete digital twin of the station, based on a mechanistic activated sludge model (ASM family) enriched to estimate N₂O. It reproduces the physical and biological functioning (alternating anoxic/aerobic zones, aeration/anoxia phases), calibrates itself using site data, and allows off-site testing of operating strategies before actual application.

The twin is used to evaluate more advanced control strategies by targeting the phases when N₂O is most likely to appear, particularly during transitions between aerated and anoxic states. The analyses also show constraints in intermittent aeration: oversized blowers reduce the fineness of adjustment and complicate the trade-off between energy savings and N₂O peak reduction.

To make the approach industrializable and replicable, the simulation was replicated in open source code within eWatLink, in the form of packages, without dependence on a commercial license.

Auto-calibration and software sensor. Auto-calibration has been developed to accelerate deployment on new WWTPs: once the hydraulics and basins have been defined, the tool automatically explores settings and identifies those that best align with the measurements. Finally, this work paves the way for an N₂O software sensor, estimating N₂O from process data and the calibrated twin, to reduce costs and ensure continuous monitoring.

The eWatLink project is co-financed by the Walloon Region (BEWARE program) and the European Commission (Horizon 2020 research and innovation program).

Development of Microbial Bioindicators and Biomarkers for Water Quality Assessment

Fate and Removal of Antibiotics and Antibiotic Resistance Genes in a Rural Wastewater Treatment Plant

Who is actually affected by the reform and what is its impact?